Directed assembly of anisotropic nanoparticles by Convective Self-Assembly

NANOSCIENCE

Lab: LPCNO

Duration: NanoX master Internship (8 months part-time in-lab immersion) 6 months full-time internship

Latest starting date: 2023-02-01

Localisation: Nanotech team at LPCNO, located in the INSA campus

Supervisors:

Giuseppe BONIELLO boniello@insa-toulouse.fr

Laurence RESSIER laurence.ressier@insa-toulouse.fr

This research master's degree project could be followed by a PhD

Work package:

The ability to assemble nanoparticles into specific patterns is fundamental for any application which requires miniaturization in functional devices, such as sensing, plasmonics, anticounterfeiting, or micro- and nano-electronics. Moreover, in the case of anisotropic nanoparticles, there is the possibility to stack them into ordered assemblies, with advantages in terms of compactness, mechanical stability, oriented mesoscopic properties, and their enhancement provided by the uniform arrangement of these building blocks.

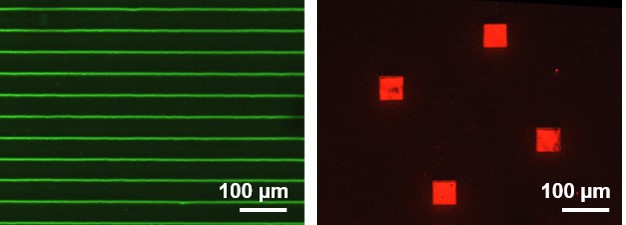

A suitable experimental method for particle deposition is Convective Self-Assembly (CSA). CSA involves the translation of a meniscus of colloidal suspension on a solid substrate. A combination of convective flows induced by evaporation and attractive capillary forces at the triple line between air, substrate and colloidal solution ensures accumulation of particles in this zone and assists deposition [1]. This technique allows to assemble mono- and multi-layers, 1-D and 2-D patterns of colloidal particles within a large range of sizes [2, 3]. While the assembly of particles in aqueous solution is already addressed and understood, the behavior for non-polar solvents remains unclear. In this framework, the main objective of this internship will be to study the deposition by CSA of anisotropic quantum dots in non-polar solvents and in liquid crystals onto bare, functionalized and/or patterned substrates. Different kinds of quantum dots will be considered in the experiments in terms of size, shape and material.

The candidate will work in a clean room and will have access to various microfabrication techniques (photolithography, nano-imprint lithography, laser lithography…) to create chemically, electrically and topographically functionalized surfaces and/or patterns. He/she will deposit quantum dots by CSA technique; analyze the assemblies by fluorescence microscopy, atomic force microscopy (AFM) and scanning electron microscopy (SEM); predict their behavior by numerical simulation (as a part of ongoing collaboration with LGC – Toulouse). All the experimental set-ups are available on site.

The results could be of interest for the development of innovative applications, in collaboration with industrial partners, such as high-efficiency photoemissive devices or micro-displays for AR and VR.

References:

[1] Malaquin, L.; Kraus, T.; Schmid, H.; Delamarche, E.; Wolf, H. Controlled Particle Placement through Convective and Capillary Assembly. Langmuir 2007, 23, 11513−11521.

[2] Farcau, Cosmin, Neralagatta M. Sangeetha, Helena Moreira, Benoît Viallet, Jérémie Grisolia, Diana Ciuculescu-Pradines, and Laurence Ressier. “High-Sensitivity Strain Gauge Based on a Single Wire of Gold Nanoparticles Fabricated by Stop-and-Go Convective Self-Assembly.” ACS Nano 5, no. 9 (September 27, 2011): 7137–43. https://doi.org/10.1021/nn201833y.

[3] Teulon, Lauryanne, Yannick Hallez, Simon Raffy, François Guerin, Etienne Palleau, and Laurence Ressier. “Electrostatic Directed Assembly of Colloidal Microparticles Assisted by Convective Flow.” The Journal of Physical Chemistry C 123, no. 1 (January 10, 2019): 783–90. https://doi.org/10.1021/acs.jpcc.8b08981.

Areas of expertise:

Nanoparticles, self-assembly, material science, microscopy, nanoxerography

Required skills for the internship:

The successful candidate will have a background in physics, physical chemistry and/or material science. Having experience in SEM or AFM techniques is a plus; in any case, training on experimental techniques will be carried out during the internship. Moreover, he/she should be dynamic, autonomous, and taking initiative. Good level of written and verbal English is required.