Tunable Nanoxerography using microfluidic functionalities

NANOSCIENCE

Lab: LPCNO

Duration: NanoX master Internship (8 months part-time in-lab immersion)

5 months full-time internship

6 months full-time internship

Latest starting date: 01/02/2023

Localisation: Nanotech, LPCNO

INSA Toulouse

135 Avenue de Rangueil

31077 Toulouse, Cedex 4

Supervisors:

Simon RAFFY, Dr raffy@insa-toulouse.fr

Etienne PALLEAU epalleau@insa-toulouse.fr

This research master's degree project could be followed by a PhD

Work package:

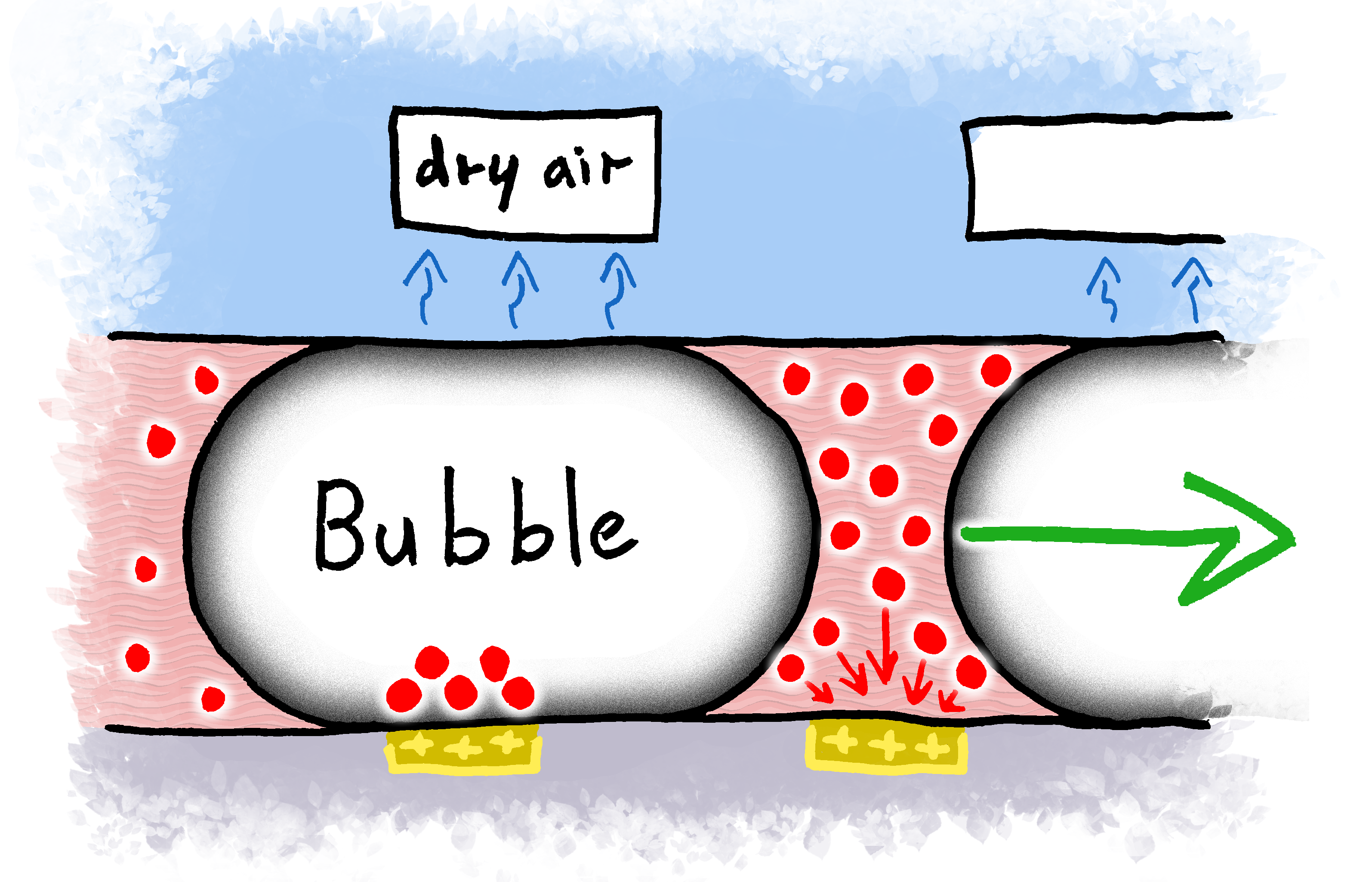

Nanoparticle patterning is a prerequisite for fabricating functional colloid based nanodevices [1-3]. In that frame, the Nanotech team is developing the nanoxerography method, an original directed assembly technique based on electrostatic interactions. [4] This process consists in two main steps: (i : injection step) electrical charge injection on an electret surface along a specific pattern and (ii : development step) immersion of the electrostatically patterned surface into a colloidal dispersion bath. Charge patterns thus act as electrostatic traps which after drying are precisely reproduced into mono or multilayered nanoparticle patterns, depending on selected configurations/parameters. For the past years, the Nanotech team has been exploring an alternative method to perform the development step directly in a microfluidic chip. [5-6] It allows in particular in situ observations of the assembly building up. But microfluidics still has not demonstrated all its capabilities supporting the nanoxerography process The idea behind this project is to keep investigating different pathways to have a better automation and reproducibility over the process, especially the dynamic control of the flow. This sophistication of the development will create new opportunities and paves the way to produce among other things original multiple nanoparticles type directed co assembly. For instance, some measurements have revealed that the final drying stage is critical and can partially destroy the nanoparticle patterns. Indeed, removal of the top layers and global shrinkage of the assembly could occur due to its porous structure. Thus, a possible approach to tackle this bottleneck is to generate a multiphasic development step induced by a specific microfluidic chip with bubbling functions [7].(cf. figure). It will create a frequential development with a cyclic meniscus and so a gradual shrinkage and reinforcement of the assembly step by step.

The selected student will be part of the Nanotech team and will be trained on state of the art fabrication and microfluidic equipements in a clean room environment. He/she will thus be able to run nanoxerography experiments on his/her own. The proposed experimental project is multidisciplinary but depending on his/her interest may include numerical analysis and Python programming/interfacing.

References:

1 - Huang, Y.-M.et al. Nanomaterials 2020, 10, 1327

2 - Triana, M. A.; Hsiang, E.-L.; Zhang, C.; Dong, Y.; Wu, S.-T. ACS Energy Lett. 2022, 7, 1001–1020.

3 - Panfil, Y. E.; Oded, M.; Banin, U. Angew. Chem. Int. Ed. 2018, 57, 4274–4295

4 - Palleau, E.; Ressier, L. Adv. Funct. Mater. 2018, 28, 1801075.

5 - Raffy, S.; Palleau, E.; Ressier, L. Reversible Microfluidic Chip. WO 2020084255 A1, 2020

6 - Raffy, S. et al. ACS Appl. Polym. Mater. 2021, 3, 801– 810

7 - Yuyang Li et al., Lab Chip, 2021,21, 1016-1035

Areas of expertise:

Microfluidic, Nanoxerography, Microfabrication, Electrostatic

Required skills for the internship:

Background in materials science or colloidal physics.

Electrostatic and hydrodynamic knowledge are a plus.